-40%

Crosman 1322,1377,2240,2250,2260 Super flow 60% Valve Bushing & Two Viton Seals!

$ 13.17

- Description

- Size Guide

Description

This is a custom made bushing to replace the stock Crosman 1322A026 bushing. With a .177" through hole the surface area increases 60% over the standard .140" hole. The dimensions are all the same except for the through hole and a .025" larger diameter where the bushing fits into the seal. Two custom made Viton 75 seals are supplied that accommodates the larger diameter. Viton 75 has excellent temperature resistance (-25F to 400F) and is slightly firmer than the original seal material. Bushing material is A2 tool steel for toughness. This is the largest flow bushing you can get that does not require any modifications to the gun.I first made one of these for my 1322. It worked fine and I saw my fps at 30 pumps go from 631 to 652 with a 10 inch barrel (14.3 grain pellet). Your results will vary depending on the modifications you have done but this bushing will increase your flow! My goal is to achieve 650 fps with less pumps from the 10 inch barrel.

I decided to offer these Super flow bushings for sale so other air-gunners could tweak their projects to the max!

I just recently got into the Crosman modification game and plan to focus my 40 years machining experience into making more unique performance parts available.

The bushings and seals have been thoroughly tested at high pressures in a comparative analysis with stock Crosman parts and I have full confidence in them.

You will receive one bushing and two seals. They fit in place the same as the stock parts.

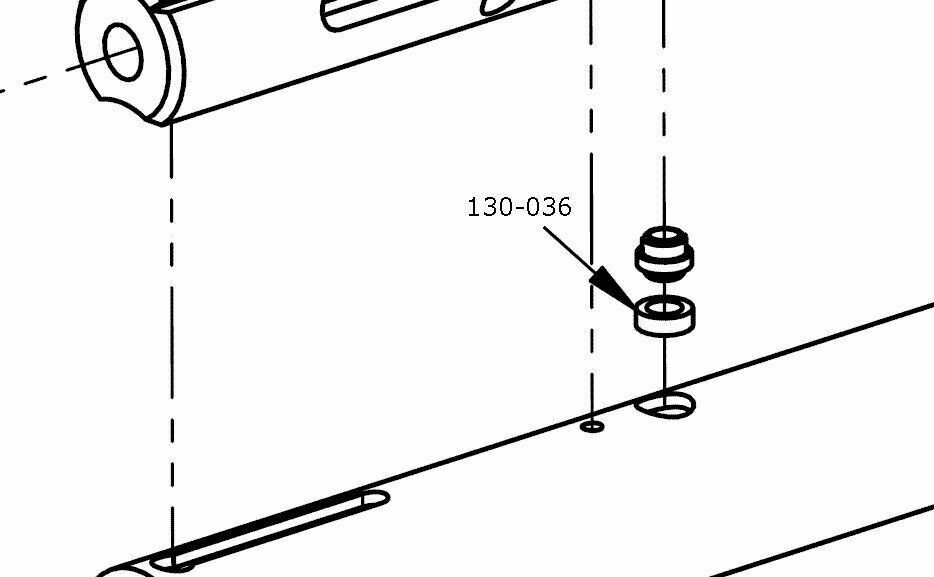

When installing any valve bushing it is critical to first square up the valve hole. In picture 9 I use the back end of a drill the size of the valve hole to rotate it square. When you install the receiver make sure the barrel set screws are loose until everything else is tightened down. This allows the barrel to settle in to the correct valve/bushing position. A crooked bushing will leak! NOTE; This squares up the valve body flat surface so it is parallel to the plane of the barrel and the hole may appear off center after squaring up- this is the correct position.

Pictures 10,11,12 show a common problem with the valve hole. It often doesn't line up perfectly and there is nothing you can do. My 1322 has a .173" hole in the valve and it just doesn't line up perfect (on my 1322 its towards the back, on my 1377 its towards the right!). With my oversized bushing you can see in the pictures how it covers the hole with no overhangs to obstruct airflow. If you have an oversized hole in your valve you need an oversized bushing. The bushing will not correct gross errors in this hole location but it will help.

The bushing and seal drop into a standard platform. No modifications to the barrel, tube or valve are required.

MY PERSONAL GUARANTEE;

I manufacture these products myself and want my customers to know I stand behind them. If you have ANY problems please contact me FIRST! I will respond in a timely manner and find a solution that suits you.

nolla_pete